Microarray Glass is a kind of granular porous glass with good rigidity and high mechanical strength. It is mainly used in the following fields:

- The production of high silica glass for bioengineering.

- Genetic engineering.

- Biological and pharmaceutical refining and curing enzymes.

Specification of microarray glass

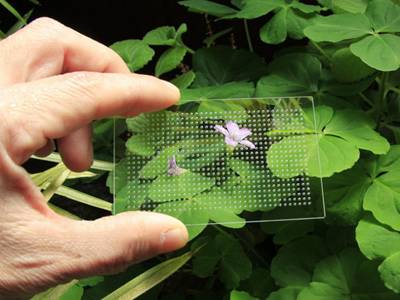

- Color: Transparent.

- Shape: Round, square and can be customized.

- Edge treatment: Polished.

- Diameter of the hole: 0.8 mm or customized as Customers' requirement.

Features and advantages of microarray glass

- Acid and alkali resistant.

- High temperature resistance.

- Good rigidity.

- High mechanical strength.

- High transparent.

Microarray glass has high transparency.

Production principle and process of microarray glass

The most commonly used additive for making such microarray glass is diatomaceous earth, the principle of which utilizes the properties of diatomaceous earth nanopores.

- After compounding silica sand, boric acid, anhydrous sodium carbonate then melted at a high temperature of 1200 to 1400 °C, and then molded at a temperature of 800 to 1100 °C (for example, tube type, rod type, plate type, particle type, fiber type and so on) to obtain unphased sodium borate glass.

- Convert it into a glass in which Na2O-B2O3 is separated from SiO2 at the heat treatment of temperature 500 °C to 650 °C.

- The soluble Na2O-B2O3 glass phase is dissolved by treatment with hydrochloric acid and hot water about 90 °C, and the remaining microarray glass which retains the original shape with SiO2 as a main component.

According to the using occasions and needs, the pore diameter, pore distribution and pore volume can be changed to prepare a microarray glass having a uniform pore diameter by controlling the change of heat treatment time and temperature.

Packaging and transportation

- To avoid rupture, the glass would be packed in a carton with a foam or bubble wrap.

- We can also package the glass according to customer's requirements.