Pressure vessel sight glass is a product used to observe changes of the medium inside chemical, petroleum, cosmetics, pharmaceutical, and other industrial equipment vessels. It helps operators to adjust or control the filling volume based on the displayed information to ensure that the medium inside the vessel remains within normal range. Installing sight glasses in containers such as liquefied gas storage tanks, tank trucks, gas-liquid phase reactors, and reaction vessels can prevent accidents caused by overfilling and avoid material imbalance due to excessive feeding.

Features

- Allow for direct visual observation of the medium inside the vessel.

- You may choose sight glass with self-washing and lighting functions to meet different work requirements.

- Have good flow control ability and closed sealing performance.

- Serve as the predominant form of visual inspection in the pipelines with large and medium diameters and medium-low pressures.

Pressure vessel sight glass

Category

By Structure

Neckless pressure vessel sight glass

Neck pressure vessel sight glass

Standard pressure vessel sight glass

By Function

Conventional pressure vessel sight glass

Pressure vessel sight glass with a flushing device

Pressure vessel sight glass with a light

Technical Data

- Casing material:carbon steel, stainless steel 316L or 304L

- Working pressure: ≤ 2.5 MPa

- Sealing gasket: NRB, PTFE, graphite, metal winding

- Window material: tempered borosilicate glass, quartz glass, tempered soda-lime glass

- Working pressure

- The maximum allowable temperature of soda-lime glass is 150 °C

- The maximum permissible temperature of borosilicate glass is 280 °C

- The maximum permissible temperature of quartz glass is 800°C

Specification

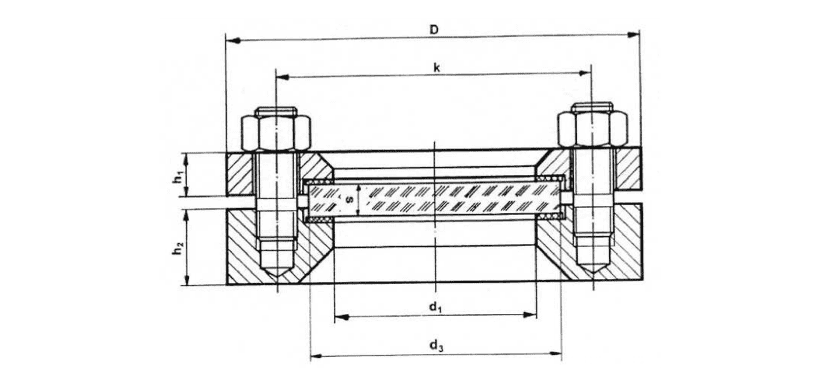

Neckless pressure vessel sight glass sketch

Table 1: Specification of Neckless Pressure Vessel Sight Glass

| Nominal Diameter d1 |

Nominal Pressure MPa |

D |

k |

h1 |

h2 |

Bolt |

| Quantity n |

Thread |

| 50 |

1.0 |

130 |

100 |

22 |

34 |

6 |

M12 |

| 1.6 |

24 |

34 |

| 2.5 |

26 |

34 |

| 80 |

1.0 |

160 |

130 |

24 |

36 |

8 |

M12 |

| 1.6 |

26 |

36 |

| 2.5 |

28 |

36 |

| 100 |

1.0 |

200 |

165 |

26 |

40 |

8 |

M16 |

| 1.6 |

28 |

40 |

| 125 |

1.0 |

225 |

190 |

28 |

40 |

8 |

M16 |

| 150 |

1.0 |

250 |

215 |

30 |

40 |

12 |

M16 |

| Unit: mm |

Neck pressure vessel sight glass sketch

Table 2: Specification of Neck Pressure Vessel Sight Glass

| Nominal Diameter |

Nominal Pressure MPa |

D |

D1 |

b1 |

b2 |

dH × S |

H |

Bolt |

| Quantity n |

Thread |

| 50 |

1.0 |

130 |

100 |

22 |

22 |

57 × 3.5 |

113 |

6 |

M12 |

| 1.6 |

24 |

24 |

116 |

| 2.5 |

26 |

26 |

120 |

| 80 |

1.0 |

160 |

130 |

24 |

24 |

89 × 4 |

120 |

8 |

M12 |

| 1.6 |

26 |

26 |

127 |

| 2.5 |

28 |

28 |

128 |

| 100 |

1.0 |

200 |

165 |

26 |

26 |

108 × 4 |

142 |

8 |

M16 |

| 1.6 |

28 |

28 |

143 |

| 125 |

1.0 |

225 |

190 |

28 |

28 |

133 × 4 |

143 |

8 |

M16 |

| 150 |

1.0 |

250 |

215 |

30 |

30 |

159 × 4.5 |

150 |

12 |

M16 |

| Unit: mm |

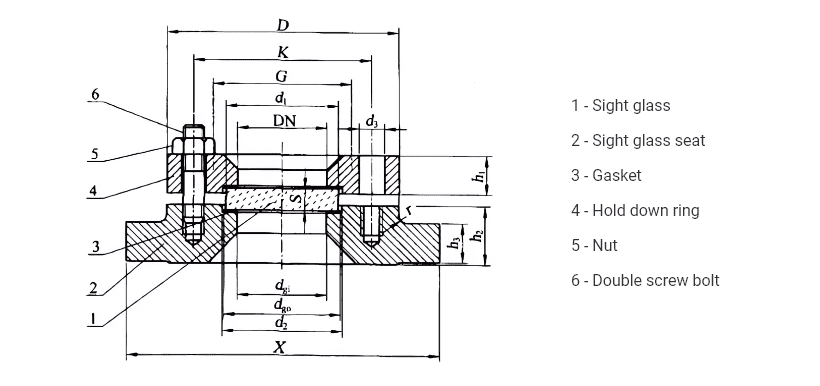

Standard pressure vessel sight glass sketch

Table 3: Specification of Standard Pressure Vessel Sight Glass

| Nominal Diameter DN |

Nominal Pressure PN MPa |

Sight Glass |

Sight Glass Lens |

Gasket |

Bolt |

| X |

D |

K |

G |

h1 |

h2 |

h3 |

d1 |

S |

dgi |

dgo |

Quantity |

Thread |

| 50 |

1.0 |

175 |

115 |

85 |

80 |

16 |

25 |

20 |

65 |

10 |

50 |

67 |

4 |

M12 |

| 1.6 |

16 |

10 |

| 2.5 |

20 |

12 |

| 80 |

1.0 |

203 |

165 |

125 |

110 |

16 |

30 |

25 |

100 |

15 |

80 |

102 |

4 |

M16 |

| 1.6 |

16 |

15 |

| 2.5 |

20 |

20 |

| 100 |

1.0 |

259 |

200 |

160 |

135 |

20 |

30 |

25 |

125 |

15 |

100 |

127 |

8 |

M16 |

| 1.6 |

20 |

20 |

| 2.5 |

25 |

25 |

| 125 |

0.6 |

312 |

220 |

180 |

160 |

18 |

30 |

25 |

150 |

20 |

125 |

152 |

8 |

M16 |

| 1.0 |

22 |

20 |

| 1.6 |

22 |

25 |

| 150 |

0.6 |

312 |

250 |

210 |

185 |

18 |

30 |

25 |

175 |

20 |

150 |

177 |

8 |

M16 |

| 1.0 |

25 |

20 |

| 1.6 |

25 |

25 |

| 200 |

0.6 |

363 |

315 |

270 |

240 |

20 |

36 |

30 |

225 |

25 |

200 |

227 |

8 |

M20 |

| 1.0 |

35 |

30 |

| Unit: mm |

Selection Guide

Users shall choose the right pressure vessel sight glass based on the medium, high working pressure and temperature of the pressure vessel.

- For pressure vessels containing highly flammable, extremely toxic, or highly hazardous media, small diameter high-temperature and high-pressure sight glasses should be used and be equipped with protective devices to prevent leakage.

- For low pressure vessels, low pressure sight glass is recommended and its diameter shall be large sizes.

- For vessels used in cold outdoor areas or there is a significant difference between the medium temperature and the ambient temperature, sight glass with high resistance to rapid temperature changes is highly recommended.

- If the location has insufficient lighting, sight glass with lighting devices should be used, and the explosion-proof rating should be chosen according to the site conditions.

Precautions

- Sight glass installation. The welding flange must be clean and undamaged, and the operation should be performed by professionals.

- Sight glass lens installation. Make sure that the sight glass seat is smooth and flat, the sealing gasket between the lens and the sight glass seat is installed properly, and the gasket is undamaged and free from grease. Before tightening the screws, make sure that the sight glass seat and the cover are installed correctly, and then tighten the screws slowly.

- For hinged or threaded sight glass devices, make sure that the sealing gasket is properly installed before operation. If necessary, re-tighten the bolts. Ensure that the sealing gasket between the sight hole and the sight glass hole is installed correctly, the connection flange is undamaged, and adjust the connection screws. It is important to ensure not only a good seal between the components connected to the sight glass lens but also a good seal between the sight glass and the welding flange, as well as keeping the pressure inside the vessel within the rated pressure.

- After installation, there should be no additional pressure applied to the sight glass, as it can cause uneven stress and lead to glass breakage.

Installation & Maintenance

- Sight glass is a device used to observe the flow and reactions of liquids, gases, and steams. The window glass should be kept clean and free from dust.

- The window glass is a fragile component, so it should be handled with care during installation.

- The glass has limitations in terms of temperature and pressure resistance, so strictly follow the instructions provided.

- Allowable rapid temperature change < 60 °C, the glass will be ruptured due to excessive temperature difference.

Applications

- Pharmaceutical

- Biofuels

- Food and beverage processing

- Chemical

- Wastewater treatment and management

For chemical storage tank