PGT-03: Precision glass tube is used as syringe with a piston.

Scraper sight glass is a kind of flat sight glass, also known as a scraping plate sight glass or brush sight glass. It is commonly used in petroleum, chemical, food and other industries. It is primarily used to observe and monitor the working reaction of the medium inside the containers to ensure production safety and product quality.

The unique scraper design allows it to be applied in media with high viscosity. It effectively cleans the surface of the sight glass from substances and deposits without stopping the machine or affecting the production progress. This not only ensures a clear observation field, but also improves the production efficiency. Additionally, the sight glass is made from corrosion-resistant materials, allowing it to adapt to various working environments with different mediums. We can also customize the size and shape of the container according to your requirements to meet specific process needs.

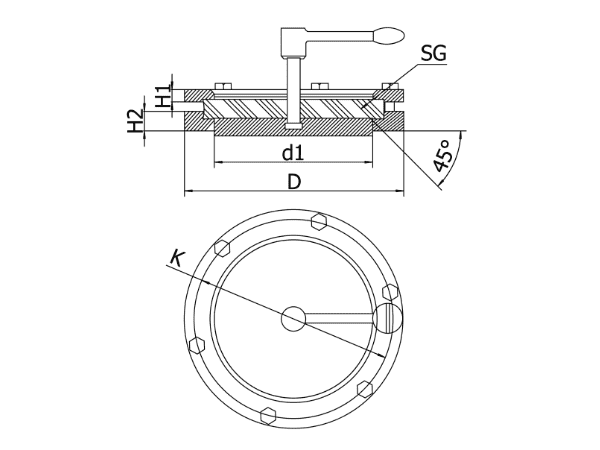

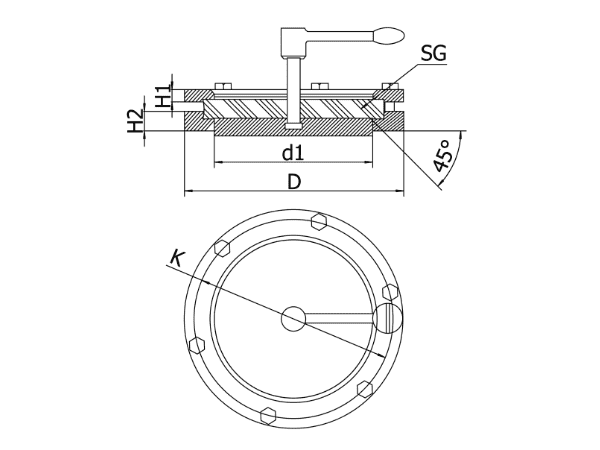

Scraper sight glass

PGT-03: Precision glass tube is used as syringe with a piston.

| d1 mm |

SG mm |

D mm |

H1 mm |

H2 mm |

K mm |

| 80 | 95 × 10 | 126 | 10 | 16 | 110 |

| 100 | 115 × 12 | 146 | 10 | 16 | 130 |

| 130 | 15 0× 15 | 182 | 10 | 16 | 166 |

OG-02: The second lens power is λ/4 and flatness is λ/10.

For pharmaceutical industry

For chemical production