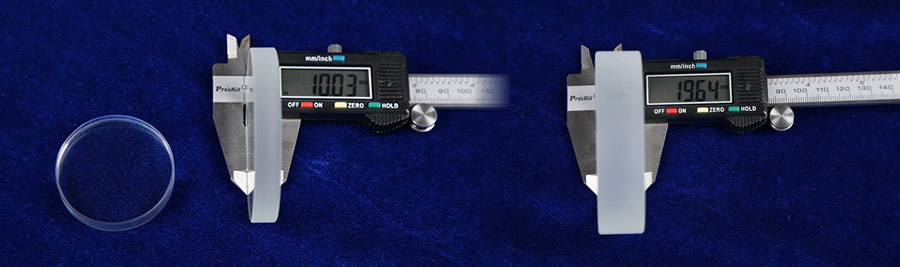

GG-01: Different dimension round sight glass with clear surface and well grinding edge finish used in flange.

Gauge glass also named sight glass or level gauge glass. According to the application requirement for pressure and temperature, different material is used. Each type max working temperature is shown below.

Round Sight glass:

GG-01: Different dimension round sight glass with clear surface and well grinding edge finish used in flange.

GG-02: Round sight glass with a hole in the center make it convenient to clear the surface of the glass.

We can produce wide range dimension of round sight glass.

| Items | Diameter (mm) | Thickness (mm) | Permissible operating pressure (bar) |

|---|---|---|---|

| RSG-1 | 30 | 15 | 200 |

| RSG-2 | 35 | 7 | 25 |

| RSG-3 | 40 | 12 | 50 |

| RSG-4 | 45 | 10 | 40 |

| RSG-5 | 45 | 12 | 50 |

| RSG-6 | 50 | 10 | 25 |

| RSG-7 | 50 | 12 | 40 |

| RSG-8 | 55 | 10 | 25 |

| RSG-9 | 60 | 10 | 16 |

| RSG-10 | 60 | 12 | 25 |

| RSG-11 | 60 | 15 | 40 |

| RSG-12 | 63 | 8 | 8 |

| RSG-13 | 63 | 10 | 16 |

| RSG-14 | 63 | 12 | 25 |

| RSG-15 | 63 | 15 | 40 |

| RSG-16 | 70 | 12 | 16 |

| RSG-17 | 70 | 15 | 25 |

| RSG-18 | 80 | 10 | 10 |

| RSG-19 | 80 | 12 | 16 |

| RSG-20 | 80 | 15 | 25 |

| RSG-21 | 80 | 20 | 40 |

| RSG-22 | 90 | 10 | 8 |

| RSG-23 | 95 | 15 | 16 |

| RSG-24 | 100 | 10 | 7 |

| RSG-25 | 100 | 15 | 16 |

| RSG-26 | 100 | 20 | 25 |

| RSG-27 | 100 | 25 | 40 |

| RSG-28 | 113 | 15 | 10 |

| RSG-29 | 125 | 15 | 10 |

| RSG-30 | 125 | 20 | 16 |

| RSG-31 | 125 | 25 | 25 |

| RSG-32 | 125 | 30 | 40 |

| RSG-33 | 135 | 25 | 25 |

| RSG-34 | 150 | 15 | 8 |

| RSG-35 | 150 | 20 | 10 |

| RSG-36 | 150 | 25 | 16 |

| RSG-37 | 150 | 30 | 25 |

| RSG-38 | 175 | 20 | 10 |

| RSG-39 | 175 | 25 | 16 |

| RSG-40 | 175 | 30 | 25 |

| RSG-41 | 200 | 20 | 8 |

| RSG-42 | 200 | 25 | 10 |

| RSG-43 | 200 | 30 | 16 |

| RSG-44 | 250 | 25 | 8 |

| RSG-45 | 250 | 30 | 10 |

| RSG-46 | 265 | 30 | 8 |

It is mainly used to observe the level of the boiler or other equipment filled with liquid, also can be used as watching glass window for thermal and chemical reaction.

Special requirement is available, such as dip hole in center, polishing edge and so on.

Transparent level gauge glass:

Transparent (smooth) level gauge glass is used to observe the liquid level of the boiler or other liquid tanks. Due to the boiler water high temperature and pressure working environment, borosilicate or aluminosilcate glass is used to meet the requirement.

GG-03: Strip gauge glass are used in industry to observing the flow of liquid and liquid level.

GG-04: Thick strip gauge glass make it can withstand acid, alkali, high temperature and high pressure.

Types:

Dimensions:

GG-05: Transparent level gauge glass drawing, the L, W and H in following chart are according to this picture.

| Items | TYPE A | TYPE B | TYPE H | TYPE TA 28 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | L | W | H | L | W | H | L | W | H | |

| TLGG-1 | 115 | 30 | 17 | 115 | 34 | 17 | - | - | - | 113 | 27,6 | 16,8 |

| TLGG-2 | 140 | 30 | 17 | 140 | 34 | 17 | 140 | 34 | 22 | - | - | - |

| TLGG-3 | 165 | 30 | 17 | 165 | 34 | 17 | 165 | 34 | 22 | 163 | 27,6 | 16,8 |

| TLGG-4 | 190 | 30 | 17 | 190 | 34 | 17 | 190 | 34 | 22 | 188 | 27,6 | 16,8 |

| TLGG-5 | 220 | 30 | 17 | 220 | 34 | 17 | 220 | 34 | 22 | 218 | 27,6 | 16,8 |

| TLGG-6 | 250 | 30 | 17 | 250 | 34 | 17 | 250 | 34 | 22 | 248 | 27,6 | 16,8 |

| TLGG-7 | 280 | 30 | 17 | 280 | 34 | 17 | 280 | 34 | 22 | 278 | 27,6 | 16,8 |

| TLGG-8 | 320 | 30 | 17 | 320 | 34 | 17 | 320 | 34 | 22 | 318 | 27,6 | 16,8 |

| TLGG-9 | 340 | 30 | 17 | 340 | 34 | 17 | 340 | 34 | 22 | 338 | 27,6 | 16,8 |

| TLGG-10 | - | - | - | 370 | 34 | 17 | - | - | - | - | - | - |

Borosilicate glass can withstand up to 400 °C, 180 bar. Aluminosilcate glass can work up to 660 °C, 180 bar.

Reflex gauge glass:

Reflex gauge glass are used to read the water level of the boiler or tank. It have 3, 4 grooves longitudinal printed on the glass. The grooves in water can help increase the angle of refraction, so the visibility of the liquid level is much better then without grooves.

With the grooving increases the angle of refraction which makes the visibility of the liquid level is much better than when using smooth glass.

GG-06: The reflex gauge glass with one groove makes the liquid level clear.

GG-07: The reflex gauge glass with more grooves can be supplied together with gasket to seal and buffer the extrusion.

GG-08: Reflex gauge glass drawing, the L, W and H of reflex gauge glass in the following chart are according to this picture.

| Size | TYPE A | TYPE B | TYPE H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L | W | H | L | W | H | L | W | H | |

| RGG-1 | 95 | 30 | 17 | 95 | 34 | 17 | - | - | - |

| RGG-2 | 115 | 30 | 17 | 115 | 34 | 17 | 115 | 34 | 22 |

| RGG-3 | 140 | 30 | 17 | 140 | 34 | 17 | 140 | 34 | 22 |

| RGG-4 | 165 | 30 | 17 | 165 | 34 | 17 | 165 | 34 | 22 |

| RGG-5 | 190 | 30 | 17 | 190 | 34 | 17 | 190 | 34 | 22 |

| RGG-6 | 220 | 30 | 17 | 220 | 34 | 17 | 220 | 34 | 22 |

| RGG-7 | 250 | 30 | 17 | 250 | 34 | 17 | 250 | 34 | 22 |

| RGG-8 | 280 | 30 | 17 | 280 | 34 | 17 | 280 | 34 | 22 |

| RGG-9 | 320 | 30 | 17 | 320 | 34 | 17 | 320 | 34 | 22 |

| RGG-10 | 340 | 30 | 17 | 340 | 34 | 17 | 340 | 34 | 22 |

| RGG-11 | - | - | - | 370 | 34 | 17 | - | - | - |

Borosilicate glass can withstand up to 400 °C, 180 bar. Aluminosilcate glass can work up to 660 °C, 180 bar.

| 1. Chemical composition | SiO2 | AL2O3 | B2O3 | Na2O + K2O | ||

|---|---|---|---|---|---|---|

| 80.00% | 2.8% | 12.8% | 3.8% | |||

| 2.Chemical Durability | Water-resistance | Acid-resistance | Alkali resistance | |||

| <0.5 mg/cm2 | <0.5 mg/cm2 | <80 mg/cm2 | ||||

| 3.Thermal stability | △T150 °C, temperature <260 °C | |||||

| 4.Bending strength | ≥1100 kgf/cm2 | |||||

| 5.Hydraulic power | -10°C, 16 kg/cm2 | |||||

| 6.Transmittance | ≥90 %/mm2 | |||||

| 7. Appearance |

|

|||||