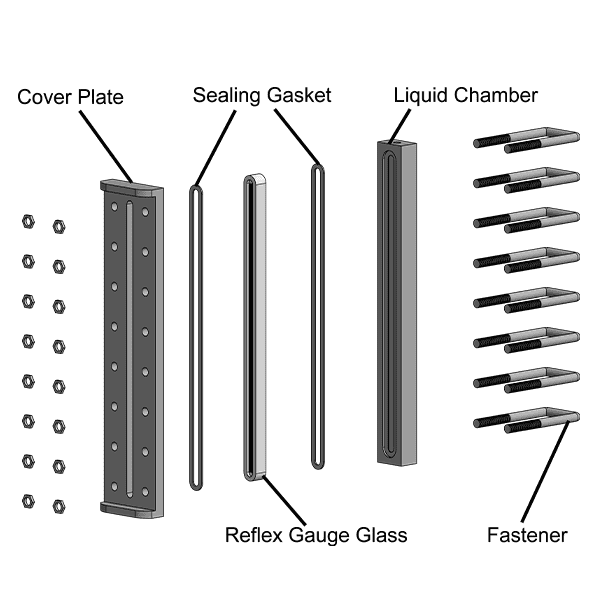

Glass plate level gauge consists of connection valve, press plates, glass, cushion, fastening bolts and nuts, drain valve, etc. It is a direct reading instruments for liquid level observation of boilers and pressure vessels, and it displays liquid level directly based on the principle of connector. It features simple structure and easy operation. Besides, the upper and lower valves are equipped with explosion relief steel balls to improve its safety. It can be matched with double-color display, lighting device and steam tracing pipe to adapt to different applications and working conditions.

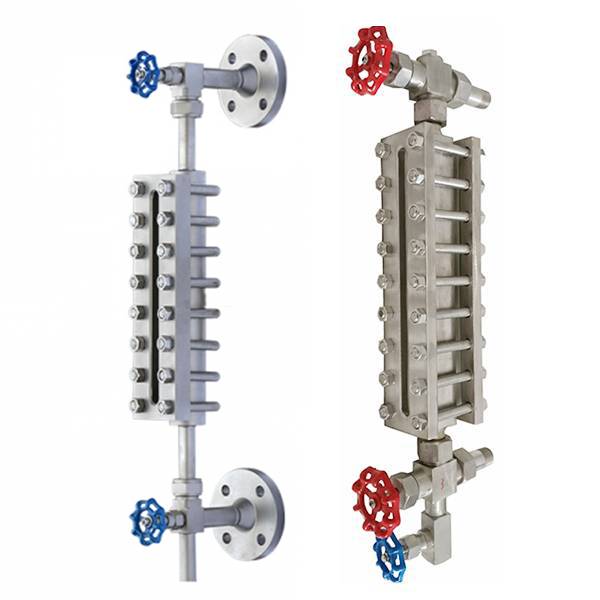

LYP-F Reflex Level Gauge

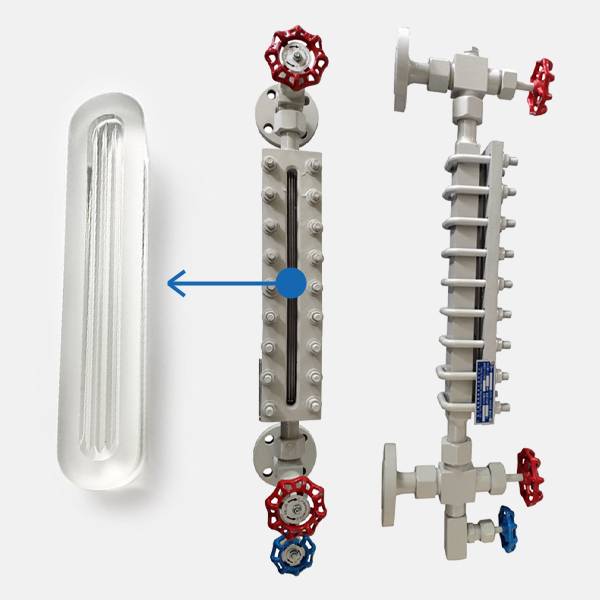

It contains a flat glass with several grooves. According to the light refraction and reflection laws, the light enters directly from the smooth surface of the glass and refracts inside the liquid, making this area become dark. However, if the light hits the air part, it reflects, making this area become bright. In this way, the liquid level is observed. It is mainly used to observe the level of colorless, transparent liquids.

Technical Data

- Measuring range: 300–2000 mm

- Working pressure: ≤ 10 MPa

- Working temperature: -20 °C to 450 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: carbon steel, stainless steel, titanium

- Glass material: toughened high borosilicate glass, quartz glass, aluminosilicate glass

- Connection: thread, flange, clamp, welding

- Display: single color, double color (air displays red and water displays green)

LYP-T Transparent Level Gauge

It mainly consists of a chamber and 2 transparent flat glasses installed before and after the chamber. The light enters from the back of the level gauge to illuminate the chamber between the two glasses, so that the operator can observe the liquid level from the front. It is mainly used to observe the level of opaque or colored liquids.

Technical Data

- Measuring range: 300–3000 mm

- Working pressure: ≤ 10 MPa

- Working temperature: ≤ 450 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: stainless steel 301, 316L, carbon steel

- Glass material: borosilicate glass, aluminosilicate glass, quartz glass

- Connection: flange, thread

- Surface treatment: galvanized, lacquer finish

- Display: single color, double color (air displays red and water displays green)

Other Products

Additionally, we also provide high temperature resistant, high pressure resistant, no blind zone and mica series glass plate level gauges.

LYP-G High Temperature Resistant Transparent Level Gauge

Mica plate is placed between the glass plate and the medium to prevent the glass from being corroded by medium and suit to the liquid level measurement under high temperature conditions for a long period.

- Measuring range: 300–3000mm

- Working pressure: ≤ 22 MPa

- Working temperature: ≤ 550 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: stainless steel 304, 316, 321, 347

- Glass material: aluminosilicate glass

- Connection: flange, thread

- Display: single color, double color (air displays red and water displays green)

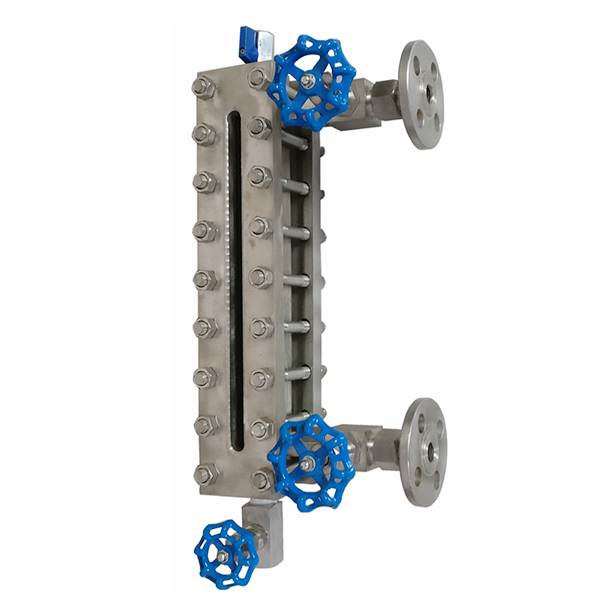

LYP-Y High Pressure Resistant Transparent Level Gauge

The liquid chamber, cover plate and valves are made of 20# and stainless steel to adapt to the liquid level measurement under high temperature and high pressure conditions for a long period.

- Measuring range: 300–3000mm

- Working pressure: ≤ 22 MPa

- Working temperature: ≤ 450 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: stainless steel 304, 316, 321, 20#

- Glass material: aluminosilicate glass, borosilicate glass

- Connection: flange, thread

- Display: single color, double color (air displays red and water displays green)

LYP-W No Blind Zone Transparent Level Gauge

Glass plates on both sides are arranged in a staggered pattern. The blind zone of one side can be observed from the other side, thus eliminating the blind zone problem exists in ordinary glass plate level gauge to achieve the purpose of continuous indication within the whole measuring range.

- Measuring range: 300–3600mm

- Working pressure: ≤ 16 MPa

- Working temperature: ≤ 450 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: stainless steel 304, 316L, 20#

- Glass material: borosilicate glass, aluminosilicate glass

- Connection: flange, thread

- Display: single color, double color (air displays red and water displays green)

LYP-B69H Mica Double Colored Boiler Liquid Level Gauge

Mica series double colored liquid level gauges are a local instrument specially designed and manufactured for monitoring the liquid level of the boiler drum of the thermal power set. It can realize remote monitoring if it is equipped with a supporting TV monitoring system.

- Measuring range: 600, 670 mm (or customized upon request)

- Working pressure: ≤ 22 MPa

- Working temperature: saturated steam water temperature

- Visible range: 100 mm – 300 mm per section

- Material: 20#

- Display: air displays red and water displays green, double colored

- Connection: flange or welding ɸ28× 4 mm

LYP-40C 90° Quick Opening Glass Plate Level Gauge

The 90° quick opening and quick closing function of the valve at both ends of the liquid level gauge solves the problem that needle valve requires too long period for opening and closing and needs to rotate the handle for many turns. In this way, it saves the time of switching the valve to a certain extent, thus ensuring the efficiency of the normal work and maintenance.

- Measuring range: 285–2590 mm(can be customized)

- Working pressure: 1.6–6. 0MPa

- Working temperature: ≤ 450 °C

- Chamber material: carbon steel

- Glass material: borosilicate glass, aluminosilicate glass

- Surface treatment: galvanized, lacquer finish

- Connection: flange

Instrumentation Valve Types

UI-CV-F forged steel valve

- Valve body material: forged steel

- Valve rod material: 2Cr13, 316L

- Connection: flange, thread, welding

- Connection standards: ANSI, DIN, GB, JIS, NPT, BSPT, G, ZG

UI-CV-S straight gauge valve

- Valve body material: carbon steel, stainless steel 304, 316L, titanium

- Valve rod material: 2Cr13, 316L

- Connection: flange, thread, welding

- Connection standards: ANSI, DIN, GB, JIS, NPT, BSPT, G, ZG

RFL-40 cast steel valves

- Valve body material: cast steel

- Valve rod material: 2Cr13, SS316L

- Connection: flange

- Connection standards: ANSI, DIN, GB, JIS

Features

- Simple structure, easy maintenance

- Can work continuously under high temperature and high pressure conditions

- Sturdy and durable and can be used for liquid level measurement for a long period.

- It is equipped with explosion relief steel balls and can effectively avoid losses caused by accidents.

Application

Glass plate level gauge is widely used in oil, chemical, power, metallurgy and pharmaceutical fields for liquid level measurement.

Reflex level gauge for boiler liquid level measurement

Reflex level gauge for oil tank liquid level measurement

Transparent level gauge for heavy oil tank liquid level measurement

Transparent level gauge for steam boiler liquid level measurement