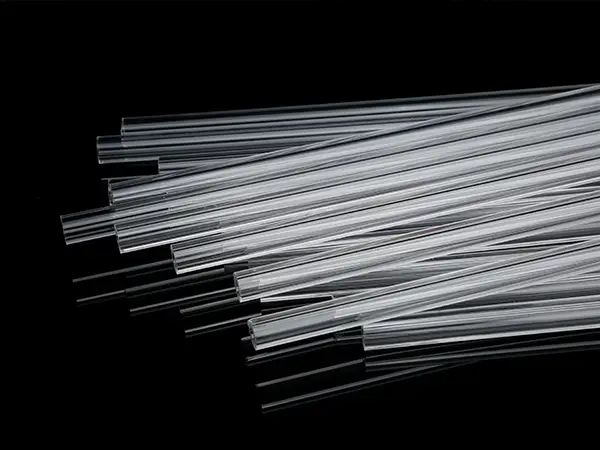

The quartz tube for curing lamps has excellent ultraviolet transmittance, significantly enhancing the efficiency of effective spectral utilization. Using high-purity materials (hydroxyl content below 1 ppm) and through strict cleanliness control, it ensures stable and continuous operation under high temperature, high pressure, and high power conditions.

Widely used in ultraviolet curing processes, it can quickly initiate chemical reactions and efficiently cure various special coatings, paints, inks, adhesives, and 3D printing materials, making it an ideal choice for various curing lamps.

| Outer Diameter Range | Outer Diameter Deviation | Wall Thickness Range | Wall Thickness Deviation | Maximum Ovality | Maximum Deviation | Maximum Bending | |

|---|---|---|---|---|---|---|---|

| CL-1 | 3< Ф ≤10 | ±0.1 | 1–2.0 | ±15% | 0.02 | 0.12 | 0.0015 |

| CL-2 | 10< Ф ≤20 | ±0.2 | 1–2.5 | ±15% | 0.0125 | 0.12 | 0.0015 |

| CL-3 | 20< Ф ≤30 | ±0.25 | 1.5–3.0 | ±15% | 0.0125 | 0.12 | 0.0015 |

| CL-4 | 30< Ф ≤40 | ±0.35 | 1.5–4.0 | ±15% | 0.0125 | 0.12 | 0.0015 |

| CL-5 | 40< Ф ≤50 | ±0.2 | 2.0–4.0 | ±15% | 0.0125 | 0.12 | 0.0015 |

| Density (20 °C kg/m 3) | Coefficient of Thermal Expansion (200-300 °C -1) | Softening Point (°C) | Annealing Point (°C) | Deformation Point (°C) |

|---|---|---|---|---|

| 2.2 × 103 | 5.6 × 10-7 | 1670 | 1210 | 1110 |

Installed between the ultraviolet lamps and substrates in ultraviolet curing systems, it can filter out infrared (IR) radiation and prevent overheating of the system and substrates, while allowing most ultraviolet radiation to pass through.