Round insulated glass

Insulated glass is a selective absorbent glass with slightly blue-green close to colorless color. It can be divided into phosphate absorption glass and silicate absorption glass. They do not absorb visible light rays significantly, but absorb a large amount of near-infrared light that generates heat. Any application that requires high light intensity and needs to be separated from heat can be applied.

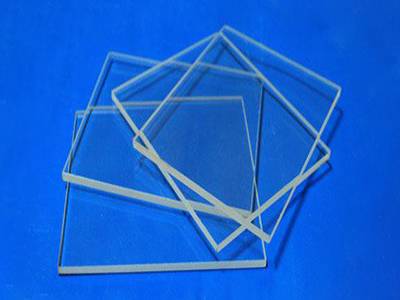

Insulated glass is slightly green and close to colorless.

Round insulated glass

Rectangular insulated glass

Insulating glass does not absorb visible light rays significantly, but absorbs a large amount of near-infrared light that generates heat. Any application that requires high light intensity and needs to be separated from heat can be applied.

The insulating glass GRB1, GRB2, GRB3, (KG1, KG2, KG3) are characterized by high transmission of visible light and effective absorption of infrared rays (especially for 1064 nm infrared absorption).

Insulating glass is used in cold light source products: such as operating room cold light, slide projector, projector.

Insulated glass for slide projector

Insulated glass for medical light

| Table 1: Insulating Glass Characteristics | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Brand | Thickness(mm) | A (2856k) | D65 | Chemical Stability | ND | a × 10-7 (/°C) | Tg (°C) | Ts (°C) | S | |||||

| x | y | Y | x | y | Y | DA | DW | |||||||

| KRB1 | 3 | 0.439 | 0.412 | 91.7 | 0.307 | 0.330 | 90.8 | 3 | 2 | 1.510 | 59 | 587 | 656 | 2.54 |

| KRB3 | 2 | 0.440 | 0.413 | 86.5 | 0.311 | 0.334 | 87.4 | 2 | 3 | 1.512 | 59 | 587 | 656 | 2.55 |

| Table 2: Insulating Glass Technical Requirements | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Brand | Thickness (mm) | 420 (nm) | 500 (nm) | 600 (nm) | 700 (nm) | 800 (nm) | 900 (nm) | 1000 (nm) | 1060 (nm) | 2200 (nm) |

| KRB1 | 3 | ≥85.0 | – | – | 45.0–70.0 | – | – | ≤4.0 | – | – |

| KRB2 | 2 | ≥83.7 | ≥83.7 | ≥80.0 | ≤61.9 | ≤30.0 | ≤9.1 | – | ≤1.8 | – |

| KRB3 | 2 | ≥81.9 | ≥81.0 | ≥76.4 | ≤50.6 | ≤12.9 | ≤2.8 | – | ≤0.1 | ≤0.9 |

| Table 3: Bubble, Article, Stress Class of Insulating Glass | ||

|---|---|---|

| Bubble | Strip | Stress |

| C | 3C | 4 |

| D-C | 3C | 4 |